Category: Press Release

PRESS RELEASE: Contractors: Make Life Easier with MCI® Construction Site Coatings!

PRESS RELEASE: Add Probiotics to Your Toilet Cleaning Routine!

Cleaning toilet bowls is not a welcome task for most people, but it must be done for good hygiene and aesthetics in home bathrooms and public restrooms. The good news is that this chore has just gotten more exciting and effective thanks to Bionetix® International’s probiotic cleaner for toilets!

Toilet Bowl Cleaner + Probiotics

ECO-CLEAN-BOWL™ is a toilet bowl cleaning tablet that adds probiotics to a septic safe cleaning formulation. Initial cleaning action cleans grime and efficiently targets and removes stains including limescale and rust. ECO-CLEAN-BOWL™ neutralizes unpleasant odors and leaves behind a fresh clean scent. But it does not stop there.

Leave Behind More Than a Fresh Fragrance

ECO-CLEAN-BOWL™ toilet cleaning tablets are enriched with beneficial probiotics that boost the toilet’s microbial ecosystem—similar to building a healthy microbiota in the human gut by eating probiotic foods and supplements. When applied to the toilet, the beneficial microorganisms of ECO-CLEAN-BOWL™ like to hang around and start building colonies in the bowl, drain, and septic system. These colonies feed on the plentiful organic matter along this path of waste disposal. By doing so, they have many positive ongoing effects, such as

- Reducing a food source for harmful bacteria

- Consuming odor-causing substances

- Decreasing the buildup of grime and dirt

- Improving drain flow and septic tank conditions

Easy to Use Toilet Tablets

Better yet, ECO-CLEAN-BOWL™ tablets are easy to use. Simply drop a tablet into the toilet bowl and allow it to fizz and dissolve before flushing the toilet. No scrubbing is required, although a toilet brush can be used for additional cleaning if desired.

Effective Cleaning

Although ECO-CLEAN-BOWL™ tablets are great for use in homes with septic systems because they lack harsh chemicals that would normally harm the microbial ecosystem, they are also an excellent choice for institutional use, coming in packs of 300 tablets per pail. Furthermore, they make an ideal option for cleaning and custodial services that need industrial strength cleaning products but also want to present an environmentally responsible image.

Make Probiotics Work for You

Microorganisms are so small that we don’t see them, but we are affected by them in many ways every day. ECO-CLEAN-BOWL™ captures the positive side of beneficial bacteria for lasting effects in restroom maintenance. Contact Bionetix® today to learn more about adding probiotics to your cleaning routine!

Keywords: probiotic cleaners, toilet bowl cleaners, cleaning routine, probiotic toilet bowl cleaner, beneficial bacteria, restroom maintenance, septic safe cleaners, Bionetix, cleaning tips

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

PRESS RELEASE: VpCI® Technology for Food and Beverage Industry: Green Corrosion Inhibitor for Food Can Protection!

For companies involved in the food and beverage industries, corrosion prevention is crucial. Corroding equipment requires costly repairs and can contaminate the product it contains. Among other materials, aluminum, tin, copper and titanium are widely used in these industries. Processed food contains diverse aqueous solutions such as syrups and additives used to improve food appearance, quality, and preservation. These foods have a wide pH range and varying salt, water and vinegar content that impacts food corrosivity. Cleaning and sanitation agents used in the industry include alkaline, acidic and oxidizing chemicals to ensure a high hygiene level. This great variety of corrosive environments and aggressive chemical agents require great cautiousness when it comes to corrosion protection. It is extremely important to follow hygiene regulations and occupational health and safety guidelines.

Cortec® VpCI® Technology is an efficient and safe solution for corrosion protection in food and beverage processing facilities. This technology helps prevent equipment damage and potential food contamination while complying to strict regulation standards. VpCI’s can be applied to protect a wide range of equipment and surfaces in food processing facilities. This equipment including cans, water tanks, and the exteriors of structures made from materials like carbon and galvanized steel, concrete or wood. Cortec® offers a broad spectrum of environmentally safe corrosion protection products that are USDA, FDA and NSF compliant. They prevent corrosion with a thin, mono-molecular protective barrier. The barrier re-heals and self-replenishes and can be combined with other functional properties for added protective capabilities.

USDA Certified, Biobased Corrosion Inhibitor for Food Can Protection

Although cans spend most time sitting on shelves in dry environments, after their production they pass through a hot steam for the sterilisation and sometimes through a cold-water bath. The exposure of the metal to steam, water and air during these stages easily leads to corrosion. Cortec’s S-8 Corrosion Inhibitor for Food Can Protection can be added at low dose and still provide excellent corrosion protection above and below the water level and at the air/water interface.

This inhibitor for food can protection is part of a wide range of Cortec®’s safe, USDA, FDA and NSF compliant corrosion protection products. S-8 is a unique, economical product, formulated only from FDA approved ingredients. Green, non-toxic inhibitor is especially useful for the corrosion protection of metallic cans with different food items during their washing or sterilization of the packed food. It is compatible with most products used in water treatment and is especially efficient against corrosion in the presence of disinfectants. It will not hydrolyze during the application. S-8 contains 71% USDA certified biobased content and is a qualified product under the mandatory federal purchasing initiative of the USDA BioPreferred® Program.

Keywords: corrosion inhibitor, can protection, corrosion protection, food processing technology, food processing facility, VpCI, VCI, USDA, biobased, food industry , beverage industry, cortec corporation

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

PRESS RELEASE: Are You Counting the Cost of Corrosion?

The global cost of corrosion was an estimated $2.5 trillion USD in 2016, according to a study published by NACE International. Allowing for inflation, that number could easily surpass $3 trillion USD today. Unfortunately, many are not aware of the high price tag of corrosion even for individual businesses and corporations. Cortec® Corporation therefore encourages manufacturers, maintenance managers, and other decision-makers to consider the potential cost of corrosion and take reasonable measures to avoid it.

Why Count the Cost of Corrosion?

Failure to count the cost of corrosion may leave manufacturers and facility managers blindsided by consequences such as faulty equipment, delayed production, and customer rust claims that must be made right. Furthermore, without counting the cost, managers may have difficulty getting the approval needed to budget time and money for corrosion prevention. Counting the cost of corrosion helps achieve both the motivation and approval needed to take corrosion protection measures.

Identifying Corrosion Costs in Manufacturing

Manufacturers who work with metal must beware of corrosion risks at every stage: receipt of goods, work-in-progress (WIP cycle), and export. Manufacturers can hope that suppliers will make good on any raw materials that arrive rusty on site, but they cannot make up for production delays or time lost negotiating the rust claim. In the WIP cycle, manufacturers lose time and sometimes metal when parts rust in between manufacturing stages and must be restored or scrapped. Export is even more dangerous. Unpredictable, fluctuating conditions inside a truck or shipping container may lead to corrosion from condensation by the time the customer receives the good. This is perhaps the costliest corrosion stage of all, as the manufacturer must remedy the damage done.

An example of how significant corrosion costs can be for manufacturers is apparent when calculating the price tag of a 1.5% economic loss due to corrosion at a hypothetical steel mill operating 24/7 and producing 100 ten-ton coils per shift, three shifts per day at a nominal material and manufacturing cost of $300 per ton. In only one week, corrosion losses could be near 100 grand. At a fraction of the cost, manufacturers could avoid most of this loss by implementing Cortec® VpCI® protective technologies and also avoiding the time lost for rework.

| Hypothetical Steel Mill Cost of Corrosion at 1.5% Loss | |

| Per Shift | $4,500 |

| Per Day | $13,500 |

| Per Week | $94,500 |

| Per Month | $410,625 |

| Per Year | $4,927,500 |

Identifying Corrosion Costs on Greenfield Projects

New oil and gas facilities or other large-scale energy projects often take years to build. Meanwhile, custom assets shipped from afar may sit one or two years before being installed. With inadequate protection, the component may be rusty and unsafe by commissioning time. Replacement could not only cost tens of thousands of dollars, but the time and distance required to make and deliver a new part could significantly delay the opening of the project. In contrast, internal protection with CorroLogic® VpCI®-339 Fogging Fluid and external protection with MilCorr® VpCI® Shrink Film could easily save not only the cost of the equipment but also the cost of the production otherwise lost by a delayed startup.

Identifying Corrosion Costs on Spares

The energy industry and other industrial plants also need critical and operational spares that can be installed quickly and efficiently if a main component fails or needs repair. Unfortunately, it is not uncommon for large warehouses to be full of rusty spares that are in no condition to use at a moment’s notice. Even though some of these individual pieces may not cost much, the total cost of corrosion from lacking a clean spare can quickly add up to millions of dollars of lost production value from downtime, along with the cost of restoration and the intangible cost of safety issues that could arise from installing a faulty component. In contrast, a Cortec® restoration and preservation plan eliminates most of these costs and headaches with solutions that are easy to apply and remove.

It’s Time to Calculate Your ROI!

Whether the calculation is done on paper or estimated mentally, counting the cost of corrosion gives a better picture of the importance of corrosion protection, allowing decision-makers to see the value of making a small relative investment in rust prevention to protect their bottom line. If you want additional guidance counting the cost of corrosion and factoring in the price of possible solutions, be sure to contact Cortec® for assistance.

Keywords: cost of corrosion, calculating corrosion cost, Cortec, preservation, WIP cycle, corrosion protection, corrosion on steel coils, oil and gas corrosion, critical spares, greenfield construction costs

Need a High-Resolution Photo? Visit: www.cortecadvertising.com

For a PDF version please click here.

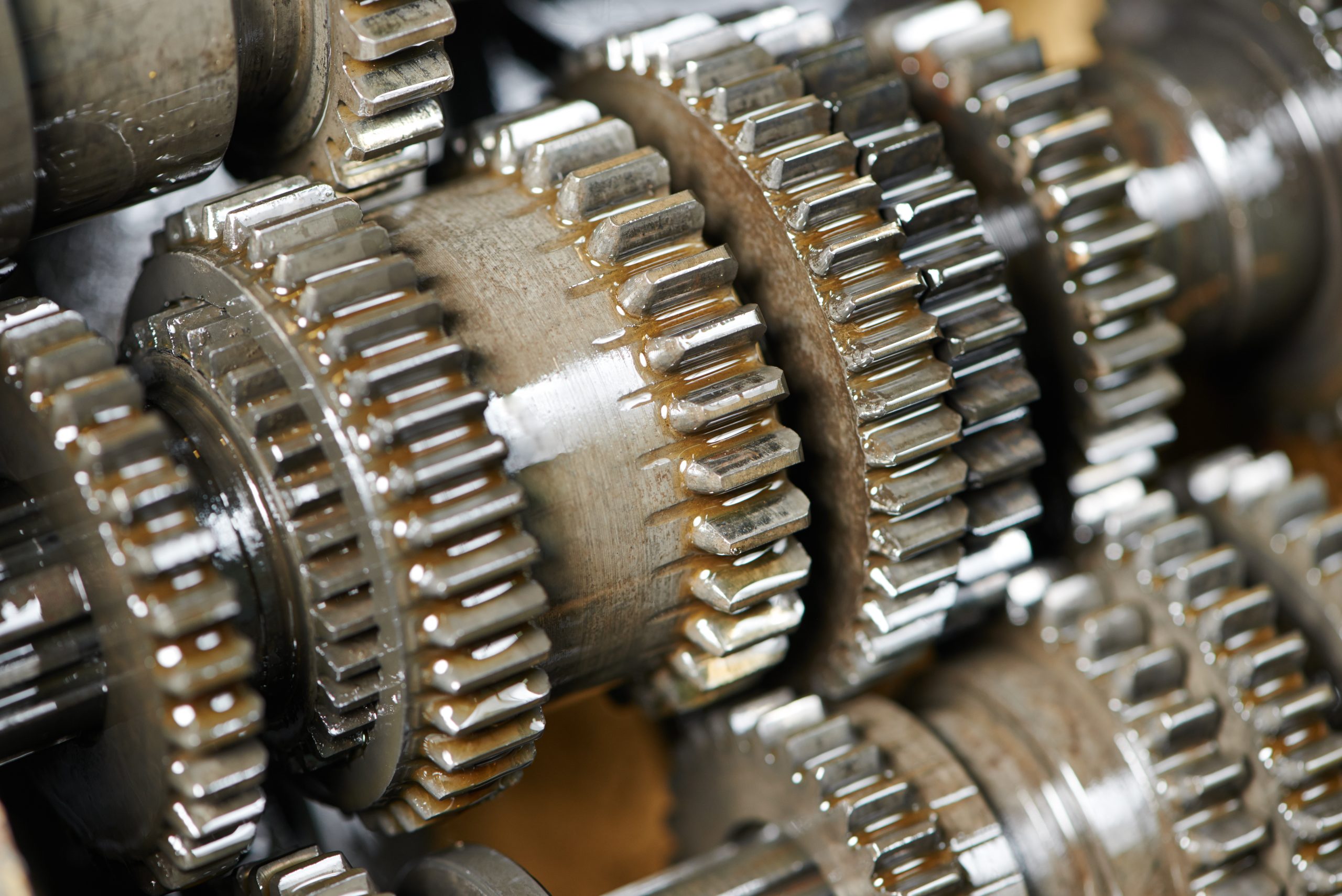

PRESS RELEASE: Make the Shift to More Efficient Gearbox Preservation!

Gearboxes are critical to many industrial activities. While good maintenance during operation is needed to ensure continued reliable performance, proper care can be just as important when the gearbox is out of service. Cortec® shares several suggestions for efficient and effective preservation of gearboxes during shipping or layup.

Standard Layup ≠ Best Practice

The traditional method of gearbox preservation is to completely fill the gearbox with oil and hope it will create a sufficient barrier against oxidation. Unfortunately, it is not economical, environmentally friendly, or practical to use such a large amount of petroleum-based material. It is also unnecessary, since Vapor phase Corrosion Inhibitors offer more thorough preservation at a much lower dose.

Protection That Goes Above and Beyond

Cortec® oil additives such as M-531 and M-535 HV protect in two ways. First, they fight corrosion on metals in direct contact with the treated oil. Second, they release corrosion inhibiting vapors into the gearbox cavity to form a protective molecular layer on metal surfaces above the oil level. This vapor-phase action means the gearbox does not need to be completely filled in order for all areas to be protected. Benefits include money saved, less oil wasted, and easier handling for workers.

Gearbox Preservation Process

Internals: Before preserving a gearbox that will be shipped or stored with gear oil inside, workers should contact Cortec® Technical Services to check additive compatibility with the oil they use. In addition to matching the right additive to the oil, Cortec® can help workers determine proper dosing based on gearbox internal volume and expected oil levels. If desired, gearboxes can even be shipped or stored completely empty by fogging a small amount of Cortec® additive inside.

Externals: Moving parts on the outside of the gearbox can be protected with temporary, (i.e., removable) coatings. VpCI®-369 leaves behind an oily corrosion inhibiting film and works well for moving components such as gear shafts. VpCI®-391 dries to a non-tacky film and is good for protection of static surfaces. If extra protection is needed for long-term/outdoor storage or overseas shipment, workers may wrap gearboxes in VpCI®-126 HP UV Shrink Film or MilCorr® VpCI® Shrink Film (extra heavy-duty) to get an external barrier with additional contact and vapor-phase protection.

Take the Easy, Effective Path to Preservation

Effective gearbox preservation is imperative to ensure that a gearbox is ready to use and continues to operate reliably for as long as possible. Cortec® VpCI® additives make this process easier, more effective, and more economical than the traditional method of filling the gearbox to the top with oil. Contact Cortec® if you need help making your gearbox layup more efficient.

Keywords: gearbox preservation, gearbox layup, efficient preservation, gearbox best practices, corrosion inhibitors, rust prevention, gearbox maintenance, gearbox storage, shipping solutions, Cortec

Need a High-Resolution Photo? Visit: www.cortecadvertising.com

For a PDF version please click here.

PRESS RELEASE: Seasonal Layups Are Not Just for Boilers: Total System Protection

Spring boiler layup season is on its way to the Northern Hemisphere. Those who approach the task with the help of Cortec’s Boiler Lizard® or Boiler Dragon™ will reap the benefits next fall by avoiding many corrosion complications during startup. However, if only the boiler is treated, facility managers may be surprised by corrosion stemming from other parts of the system. In light of this concern, Cortec® reminds boiler operators and water treatment service providers that seasonal layup is not just for boilers.

Why Worry About Corrosion?

Any part of the boiler system that handles water is at risk for corrosion during layup. This includes the deaerator/feedwater tank, steam line, heat exchangers, economizer, and condensate return lines. Unfortunately, a corrosion problem in one area can impact the others. For example, high iron levels may react with water treatment chemicals and make them less effective. Iron in the water also represents metal loss that could eventually lead to leaks and/or shortened service life. Furthermore, corrosion products can plug system components such as steam traps, reducing the efficiency of water recirculation and prompting costly repairs. Inhibiting corrosion in the entire system as part of the normal layup routine can therefore lead to valuable returns on investment.

A Corrosion Inhibitor for Every Component

Fortunately, Cortec’s water treatments are highly adaptable to multiple points of the boiler and steam system. Most traditional water treatments rely on corrosion inhibitors that only protect metal surfaces in direct contact with the treated water. However, technologies such as the Boiler Lizard® and Boiler Salamander™ also include Vapor phase Corrosion Inhibitors that diffuse throughout void spaces and adsorb on metal surfaces in hard-to-reach spaces that are partially or fully emptied.

Dry Layup: Dry layup with Vapor phase Corrosion Inhibitors works for every part of the system. Boiler Lizard® is the main go-to for the boiler water side. This water-soluble pouch of Vapor phase Corrosion Inhibiting powder protects 1,000 gallons (3.8 m³) of volume and simply dissolves when the boiler is refilled. Other options are the Boiler Gecko™ (protects approx. 100 gallons [380 L]) and the Boiler Dragon™ (one gallon protects approx. 1,000 gallons [1 L/1 m³]), Vapor phase Corrosion Inhibitor fogging fluids that can be sprayed into almost any component of a steam generation system:

- Water side

- Fire side

- Deaerator

- Economizer

- Steam line

- Superheater

- Steam side heat exchangers

- Condensate return

Wet Layup: Alternatively, some boiler components can be protected with technologies for wet-dry or wet layup. The Boiler Salamander™ works well for this purpose and can easily be added to feedwater or condensate lines and circulated without opening or draining the boiler. It protects surfaces below and above the water level and is effective at very low dosages for layup of high-purity steam boilers. While other parts of the system will inherently require dry layup, the Boiler Salamander™ is appropriate for wet layup of the following components:

- Water side

- Deaerator

- Economizer

- Condensate return

Invest Now—Reap Rewards Next Fall

Planning takes extra effort, but the corrosion prevention investment pays off in terms of the costs and headaches avoided. Those who have spent thousands of dollars on steam-trap or other corrosion-related repairs will be the most aware of how significant the ROI for comprehensive seasonal layup can be. Contact Cortec® for help to get total system corrosion protection this spring for a better startup next fall!

Keywords: seasonal layup, boiler layup, corrosion protection, corrosion inhibitor, boiler maintenance, dry layup tips, wet layup tips, Vapor phase Corrosion Inhibitors, Cortec, boiler efficiency

For a PDF version please click here.